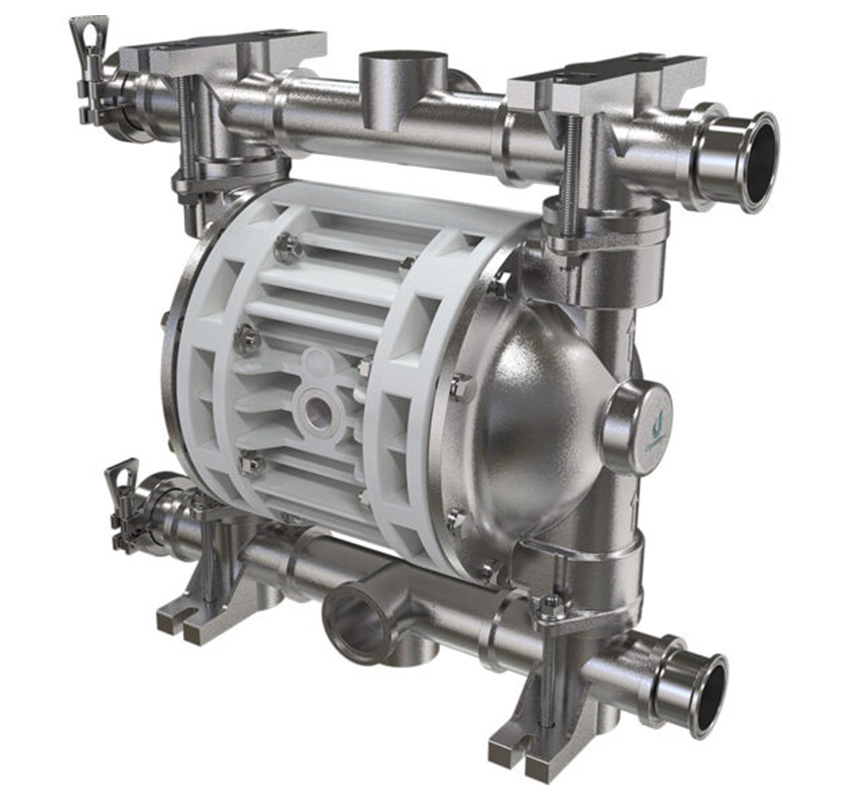

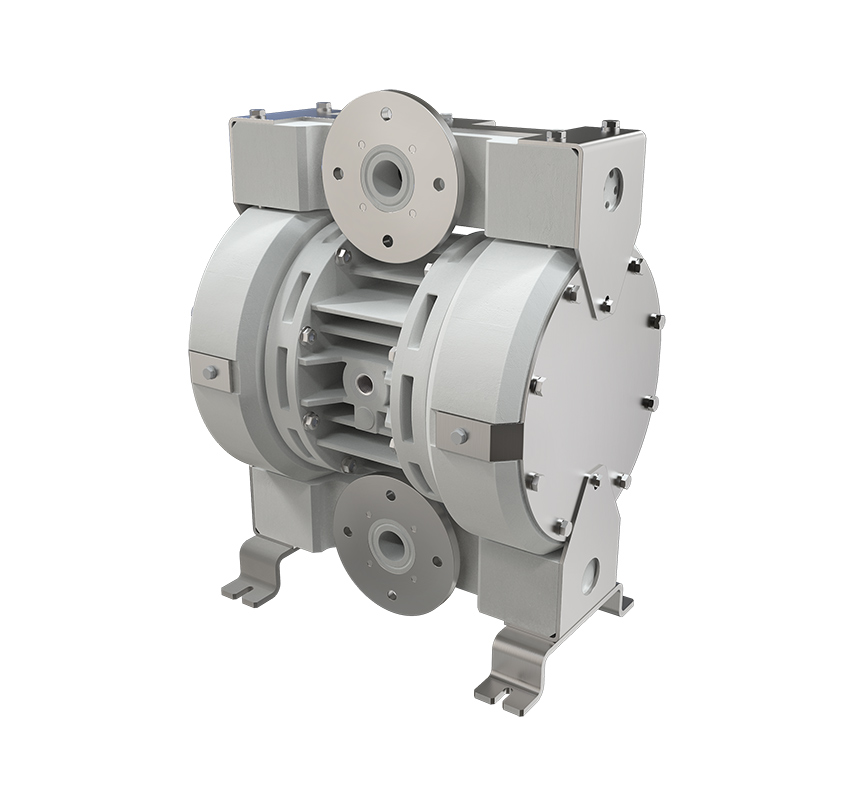

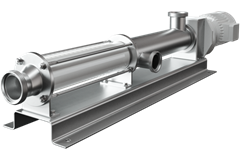

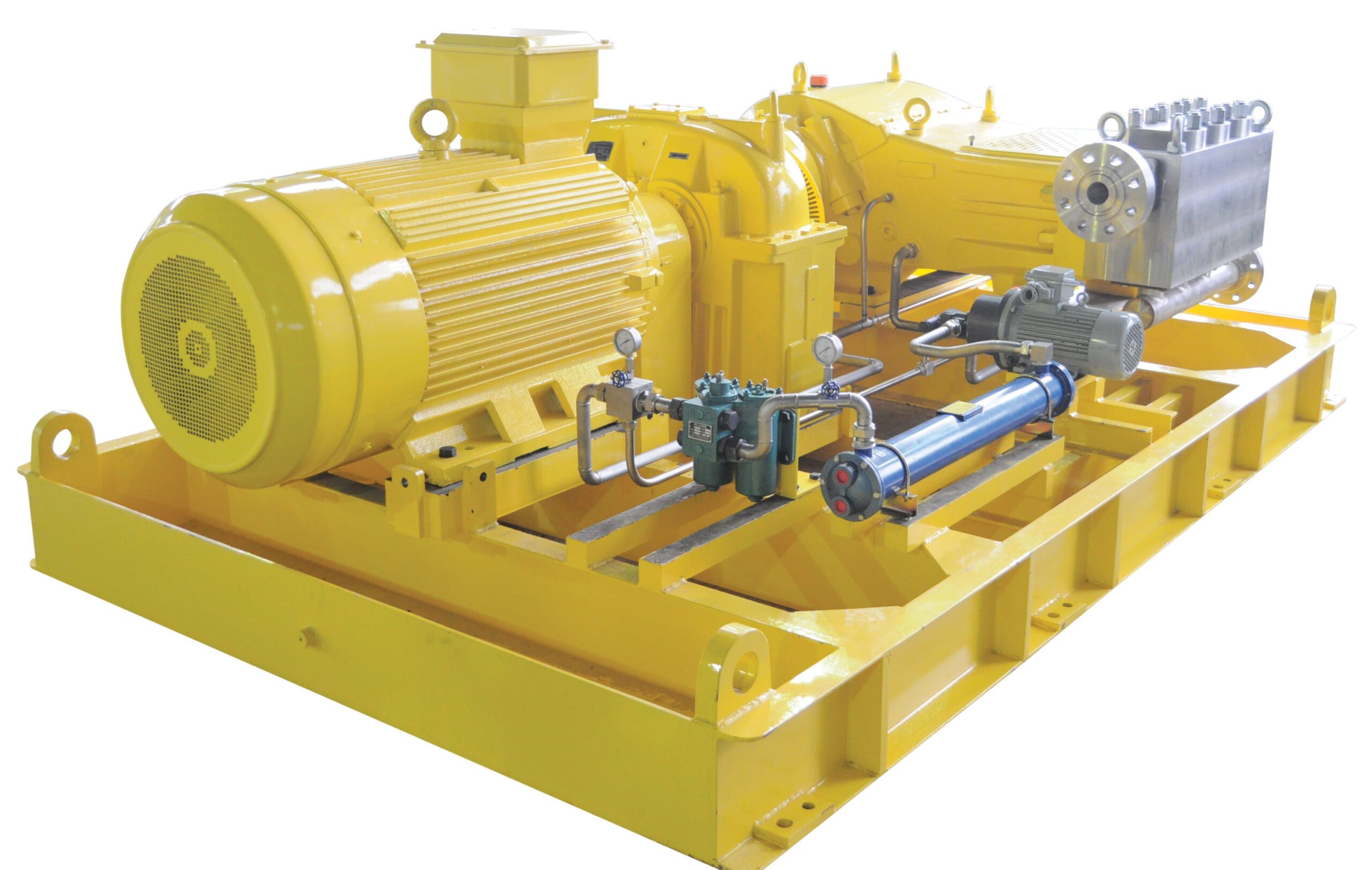

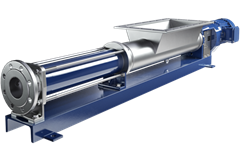

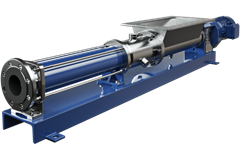

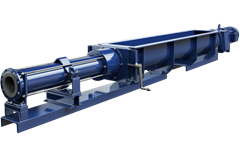

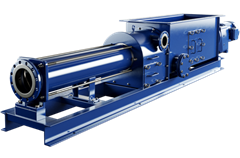

The N module forms the robust basis for all SEEPEX progressive cavity pumps. It can pump low-viscosity to viscous media, with and without solids, and can be used in virtually all industries – from the environmental industry to the chemical industry and food production. The pumps are fitted with round flanged suction and pressure connections, as well as large spherical inlet openings for the simple intake of media that contain solids.

Features and Benefits

Optimum product conveyance

Thanks to the open intake hopper and screw conveyor

Easy maintenance

Simple maintenance thanks to large inspection openings and other maintenance solutions

High system availability

Minimized maintenance times and increased system availability thanks to sophisticated maintenance concepts

Reliable

Robust design – most suitable for pumping abrasive and corrosive media

Flexible application options

Different ranges for a wide variety of applications, designed on a customer-specific basis for the respective production situation at the point of use

Range

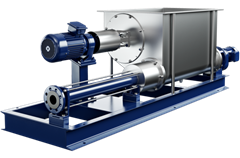

BT - STANDARD HOPPER PUMP

The allrounder with conveying screw and large hopper cross section

Conveying Capacity

0.1–150 m³h

0.44–660 US gpm

Pressure

≤ 36 bar

≤ 525 psi

BTM - WITH MACERATING SYSTEM

The cutting system in the compression zone removes coarse particles

Conveying Capacity

0.25–60 m³/h

1.1–264 US gpm

Pressure

≤ 24 bar

≤ 350 psi

BTQ - WITH RECTANGULAR HOPPER

Designed for suitable for plants with special installation dimensions

Conveying Capacity

0.05–100 m³/h

0.22–440 US gpm

Pressure

≤ 24 bar

≤ 350 psi

BTH - WITH SEPARATELY DRIVEN RIBBON SCREW

A separately driven edge-to-edge screw enables pump and feeder to operate at different speed

Conveying Capacity

0.5–40 m³/h

2.2–176 US gpm

Pressure

≤ 36 bar

≤ 525 psi

BTHE - WITH EDGE-TO-EDGE RIBBON SCREW

Large diameter ribbon screw controlled by only one drive

Conveying Capacity

0.5–40 m³/h

2.2–176 US gpm

Pressure

≤ 36 bar

≤ 525 psi

BTVE - WITH ROBUST FULL SCREW

Model particularly suitable for high dry matter contents and semi-solid products

Conveying Capacity

0.5–60 m³/h

2.2–264 US gpm

Pressure

≤ 36 bar

≤ 525 psi

BTI - WITH INTEGRATED BRIDGE BREAKER

Two counter-running paddle shafts with their own drive mix highly viscous media

Conveying Capacity

0.5–60 m³/h

2.2–264 US gpm

Pressure

≤ 36 bar

≤ 525 psi

BTEI - WITH BRIDGE BREAKER IN THE BUFFER TANK

Optional buffer tank on the hopper and separately driven paddles prevent bridging

Conveying Capacity

0.5–60 m³/h

2.2–572 US gpm

Pressure

≤ 36 bar

≤ 525 psi

BTES - HOPPER PUMP FOR SILO SYSTEMS

The lower hopper height and the large cross-section is a perfect fit for individual silo systems

Conveying Capacity

0.5–60 m³/h

2.2–264 US gpm

Pressure

≤ 24 bar

≤ 350 psi

BTEX - PARTICULARLY ROBUST HOPPER PUMP

Designed with reinforced individual components for extreme applications

Conveying Capacity

20–80 m³/h

90–350 US gpm

Pressure

≤ 8 bar

≤ 120 psi