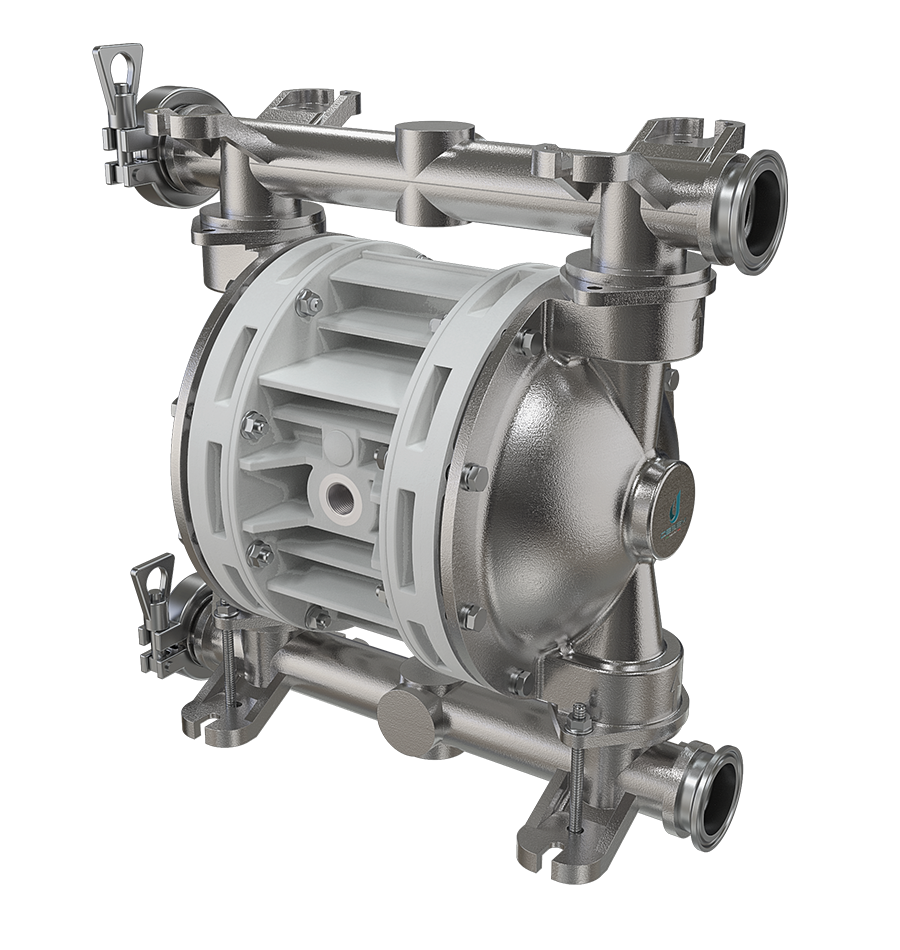

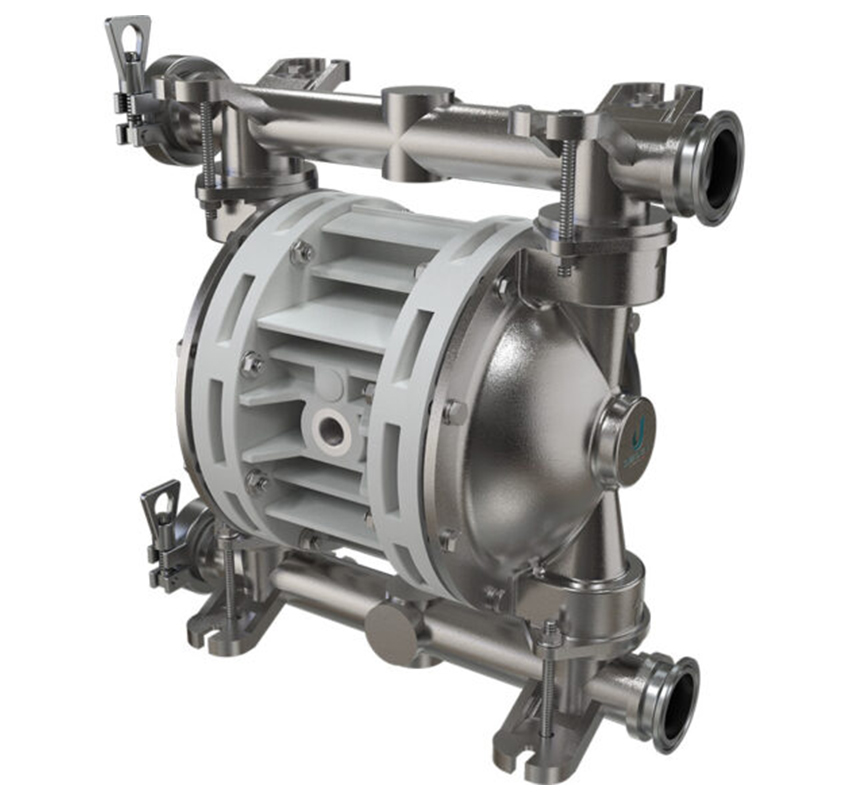

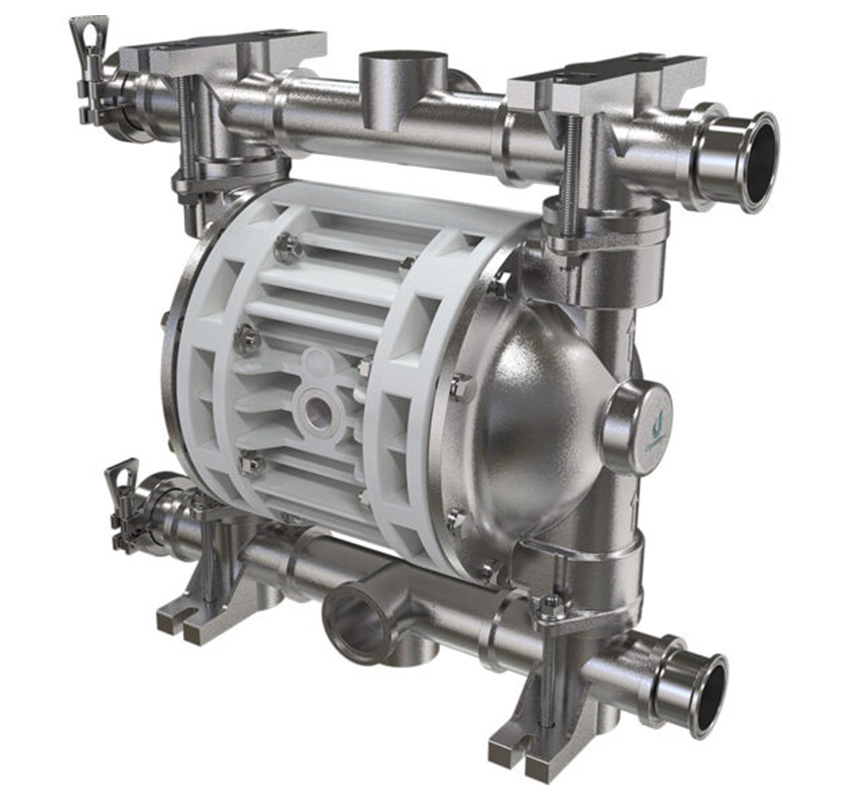

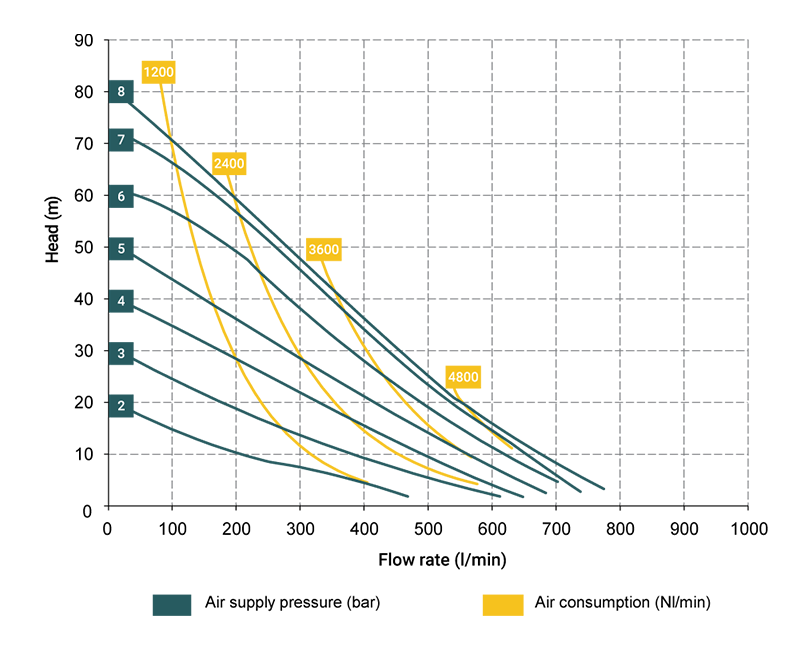

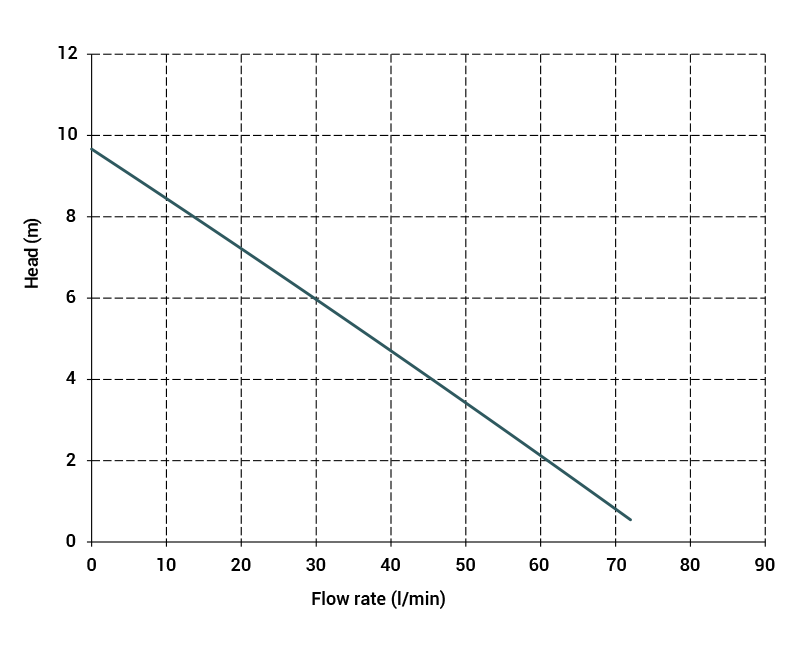

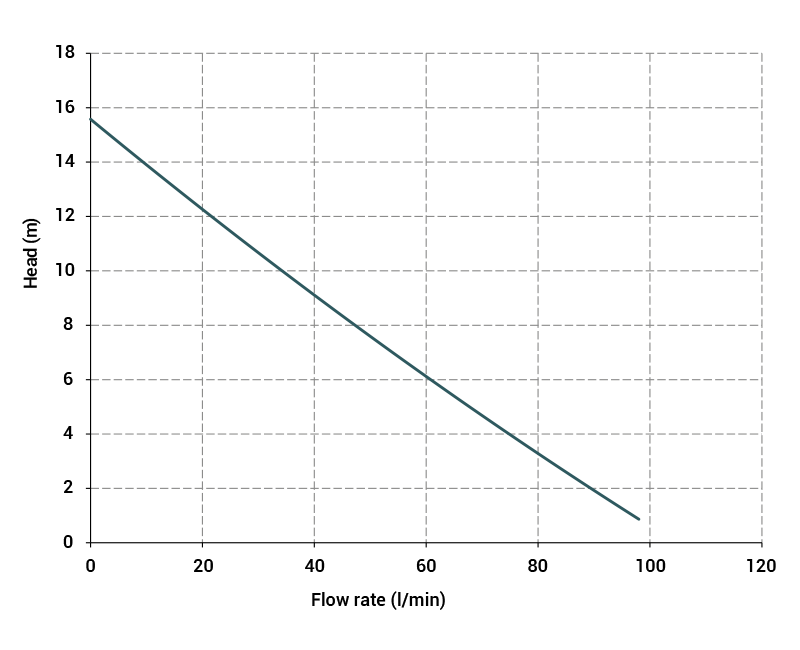

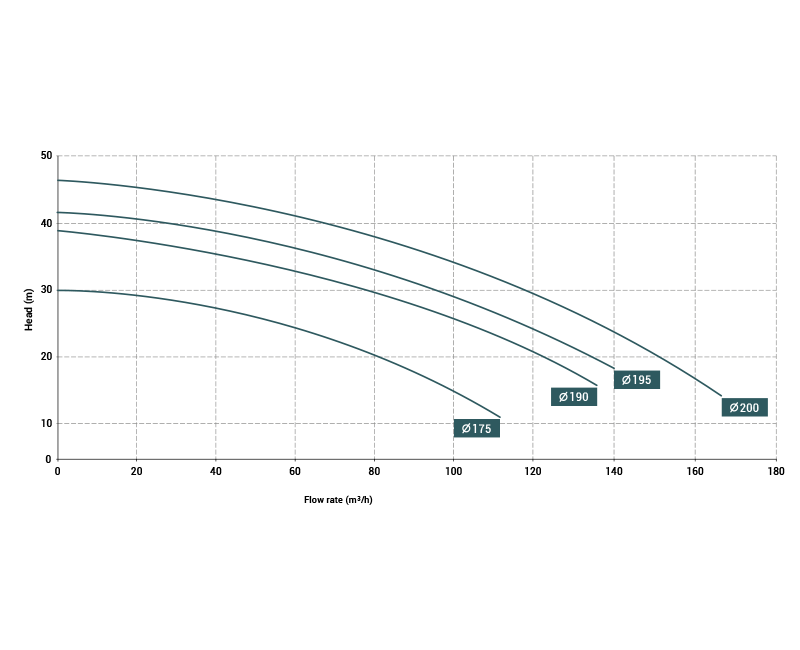

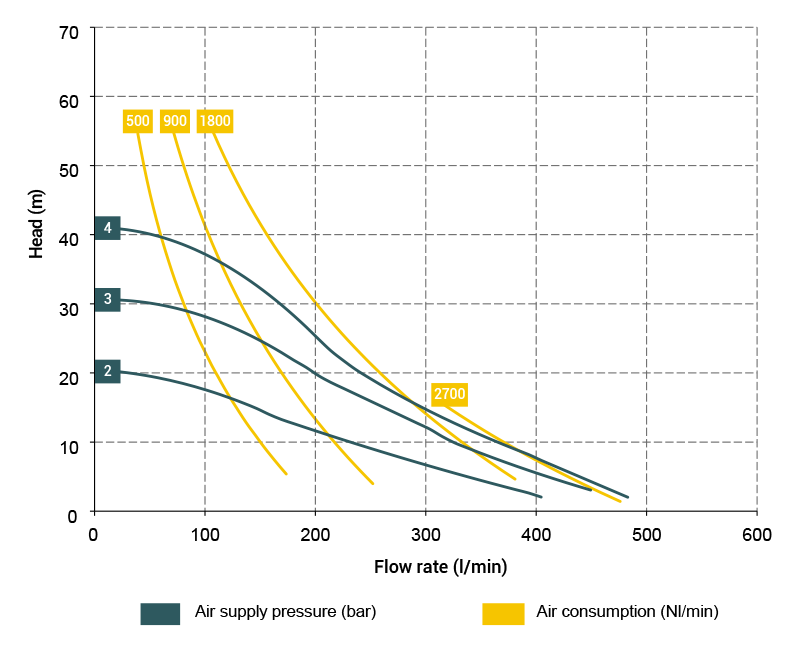

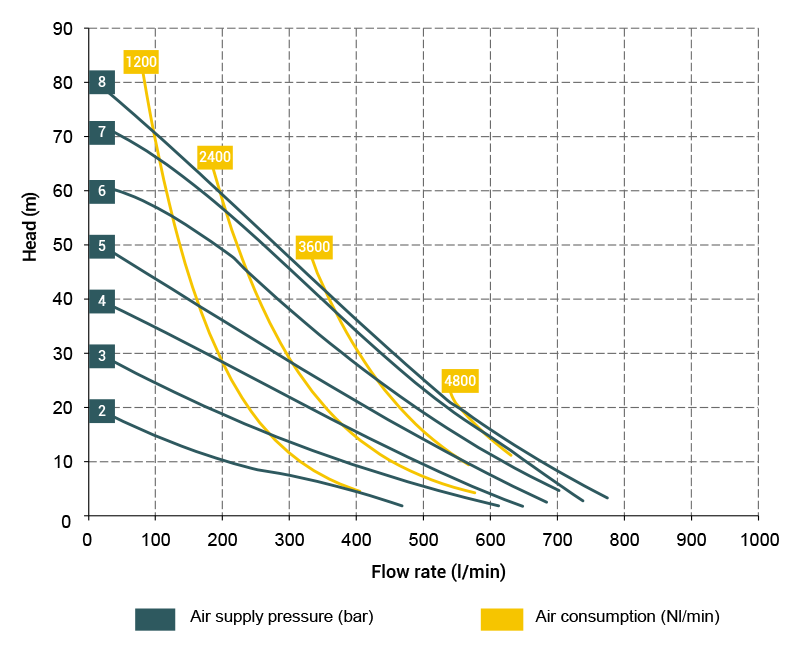

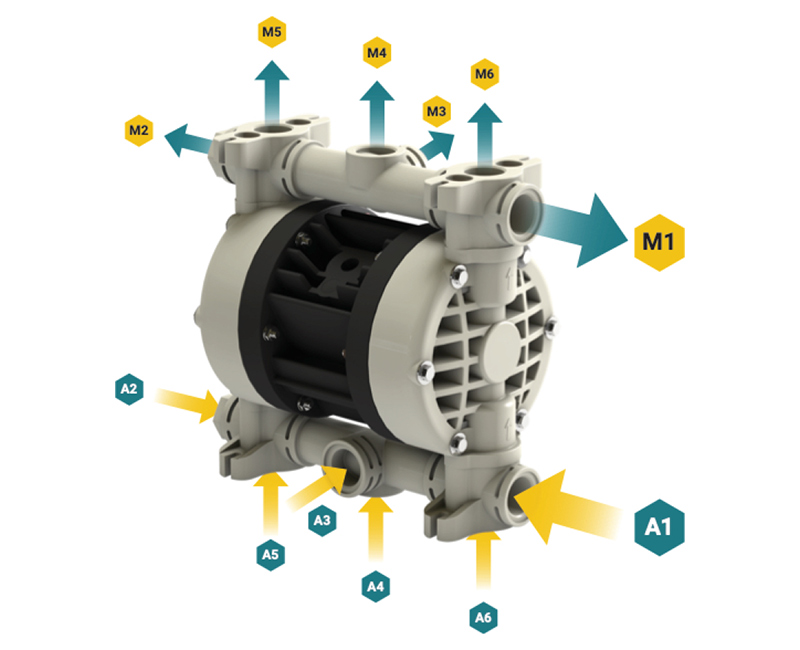

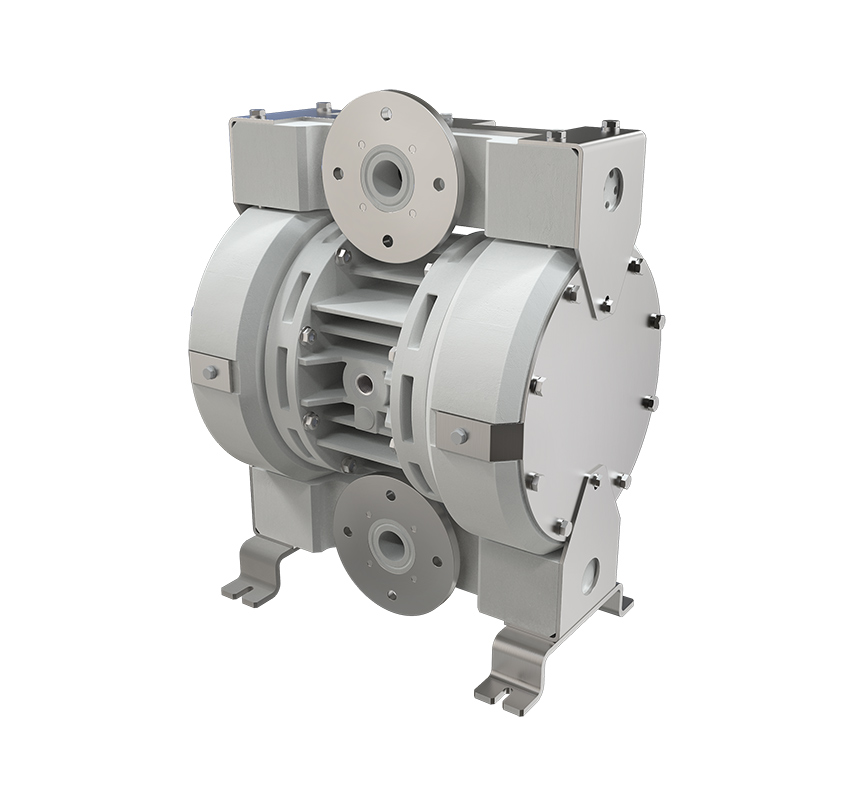

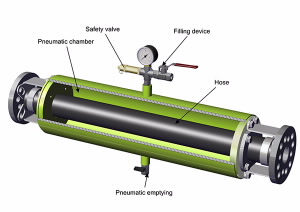

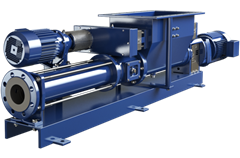

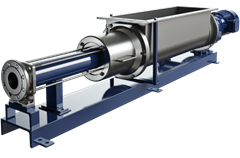

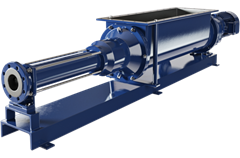

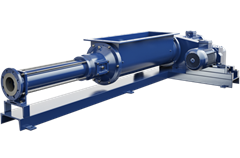

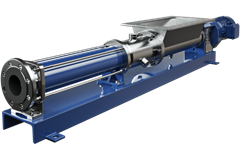

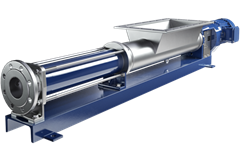

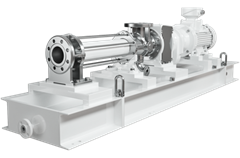

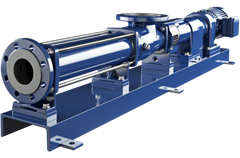

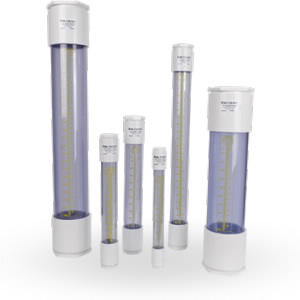

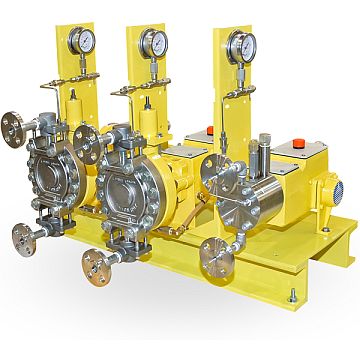

AIR-OPERATED DOUBLE DIAPHRAGM PUMPS

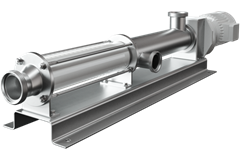

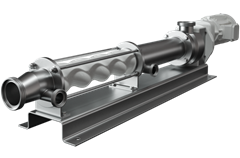

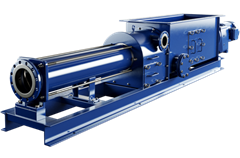

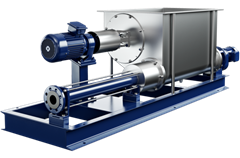

Electropolished AISI 316L pumps FDA Compliant

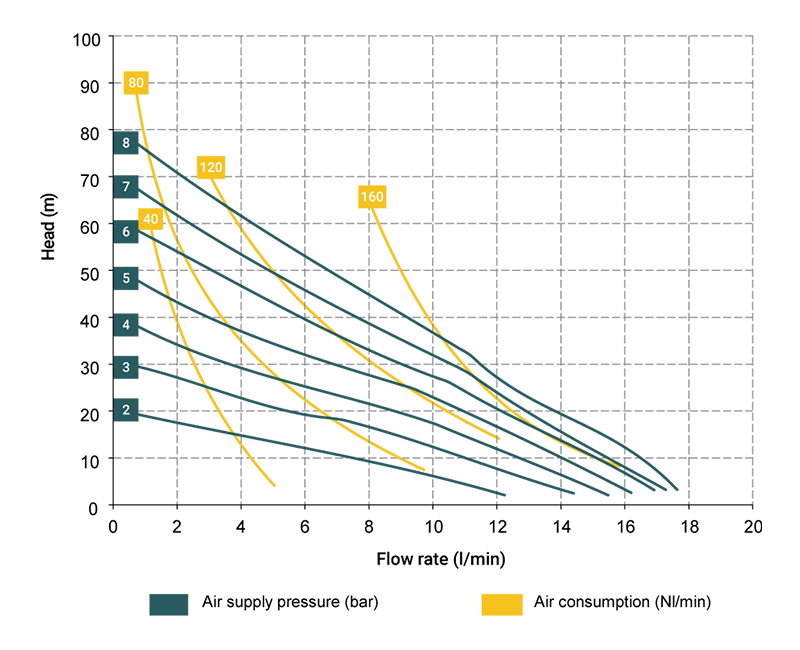

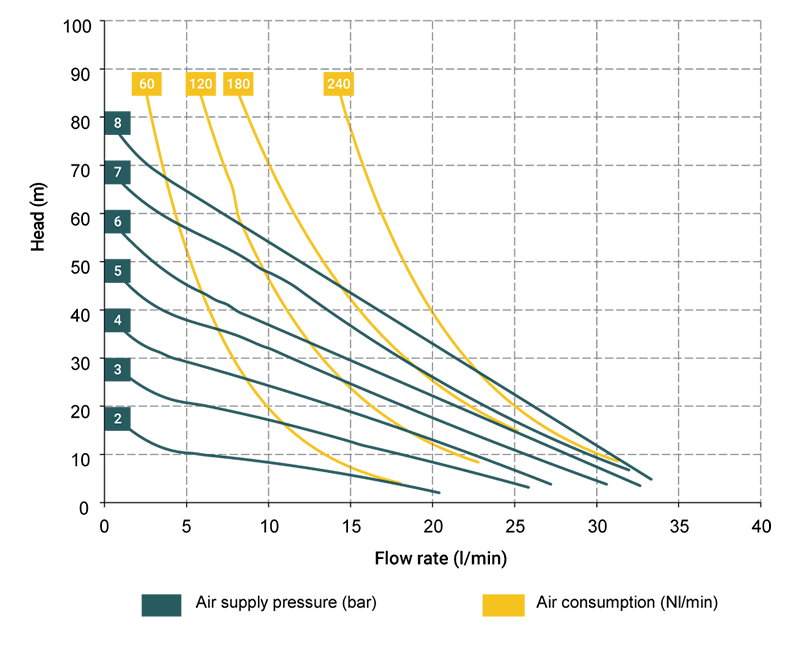

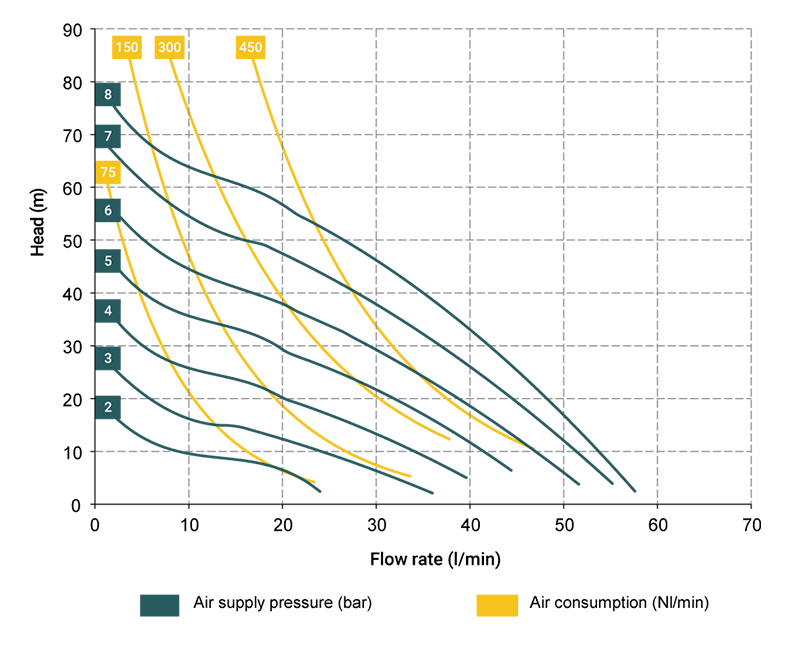

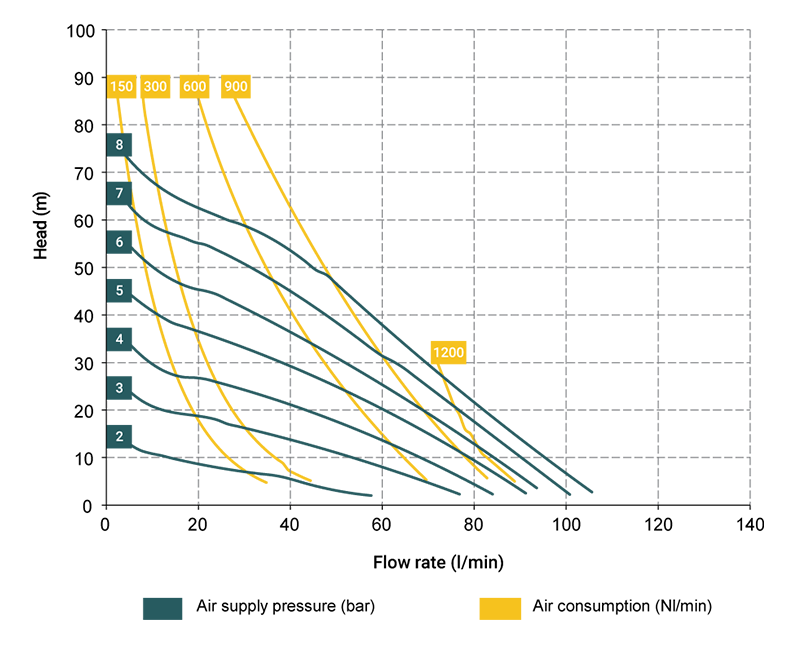

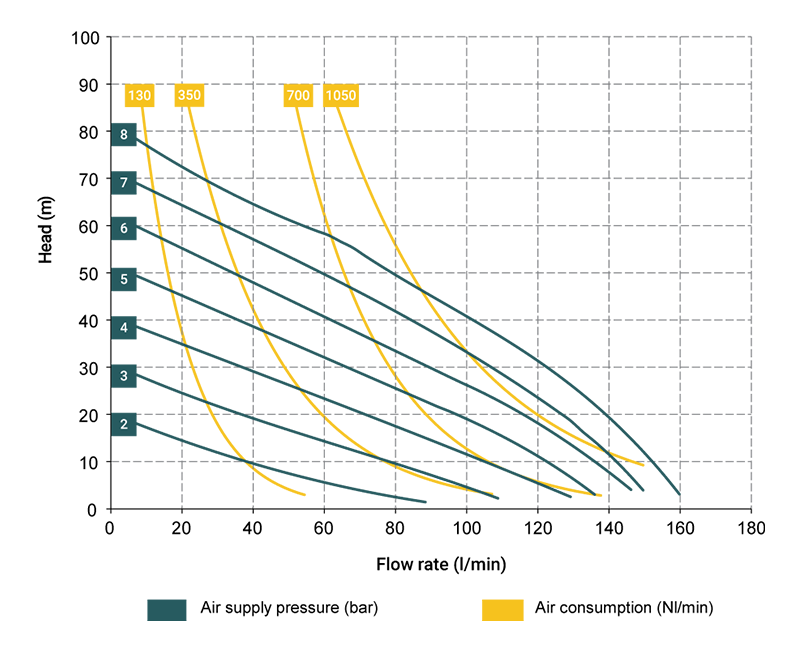

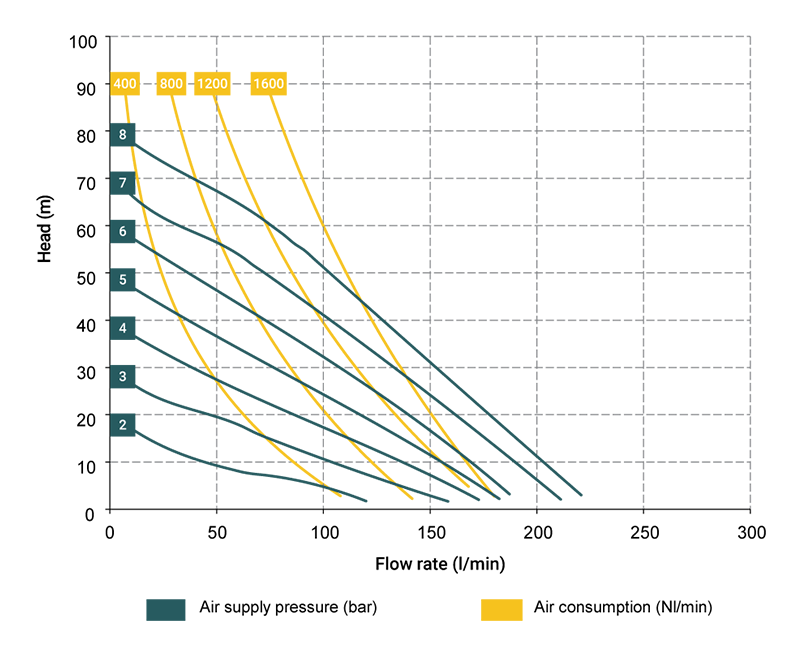

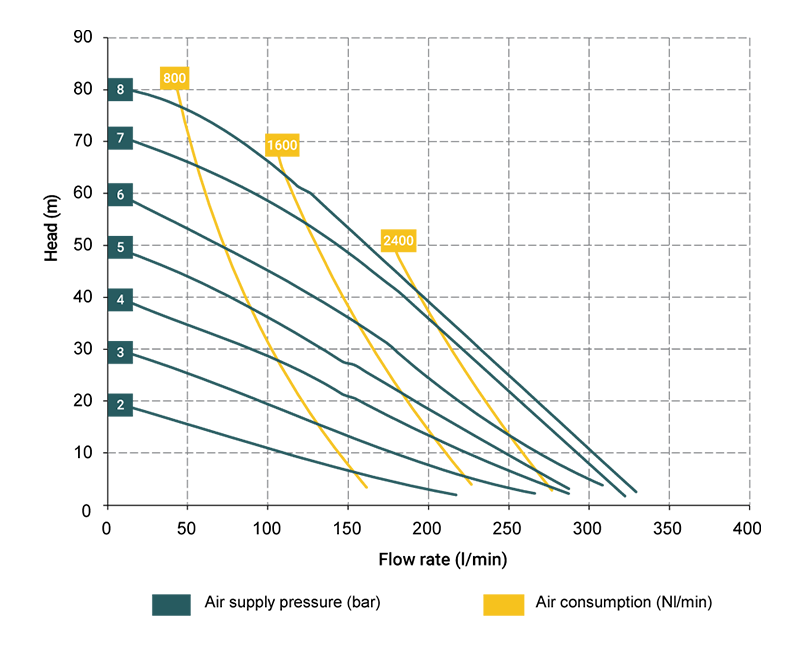

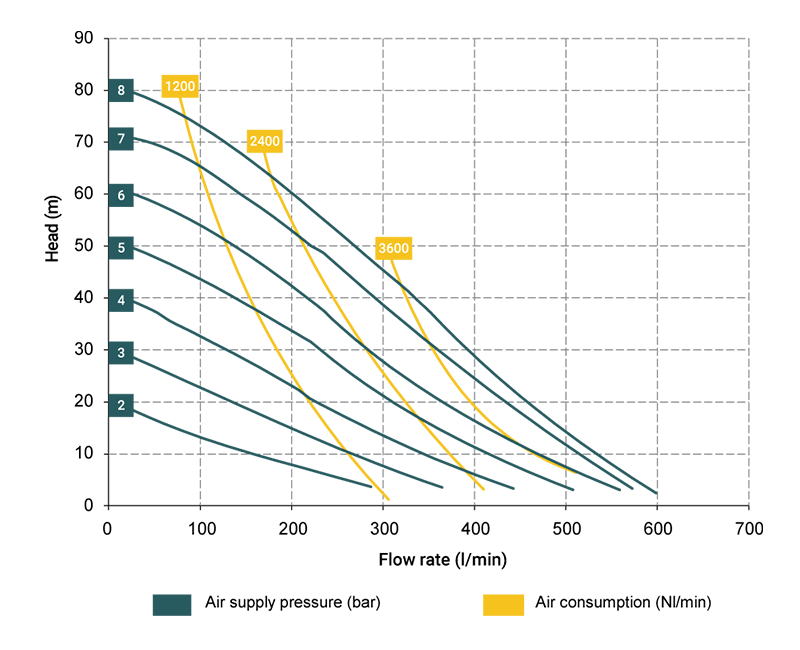

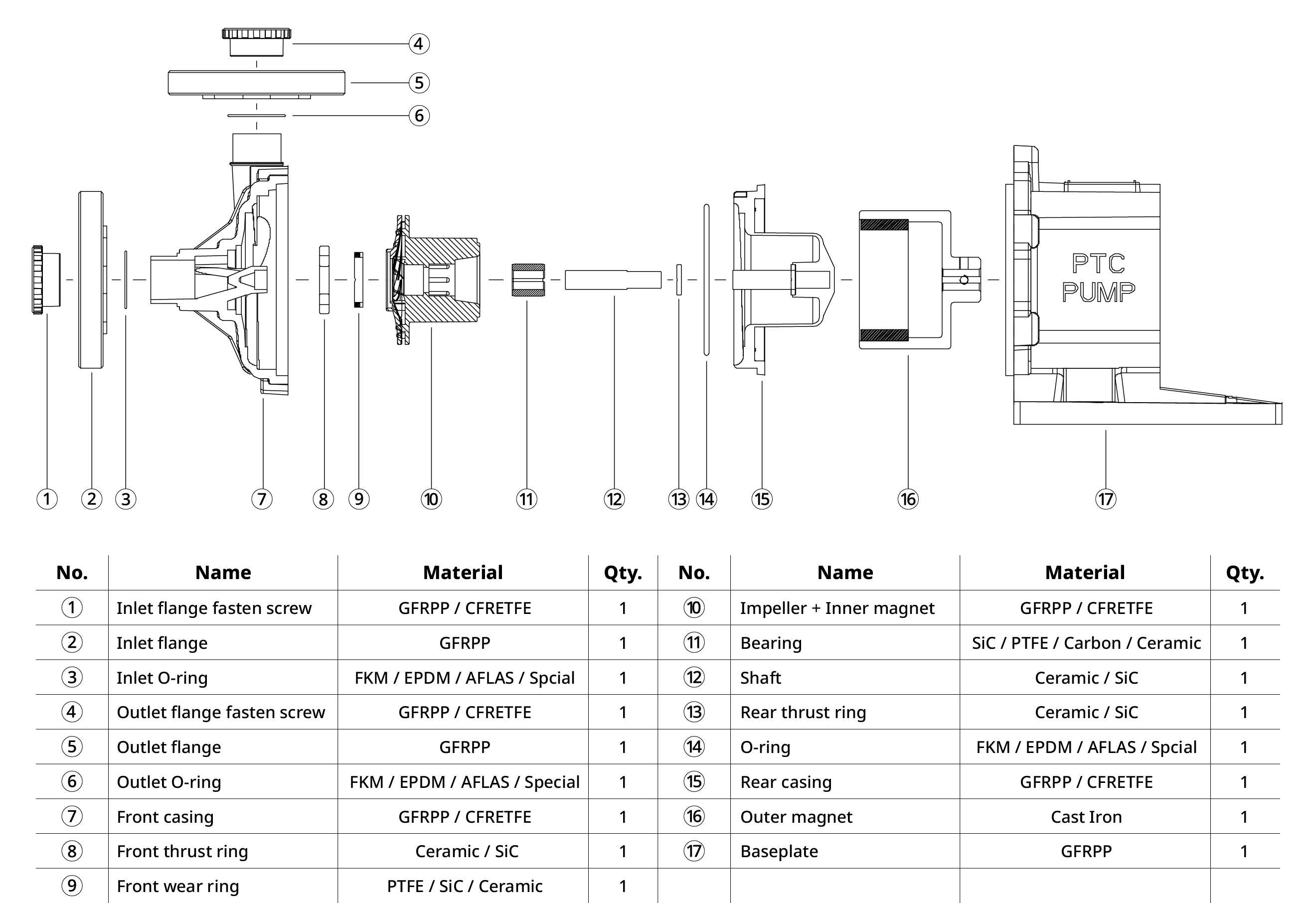

Positive displacement pumps operated by compressed air, with double diaphragm, ATEX – IECEx certified, built in AISI316 / AISI316 L Electro-polished. They are pumps suitable for handling fluids with high apparent viscosity, even in the presence of suspended solid parts. The parts in contact with the fluid are in AISI316, AISI316 L and PTFE.