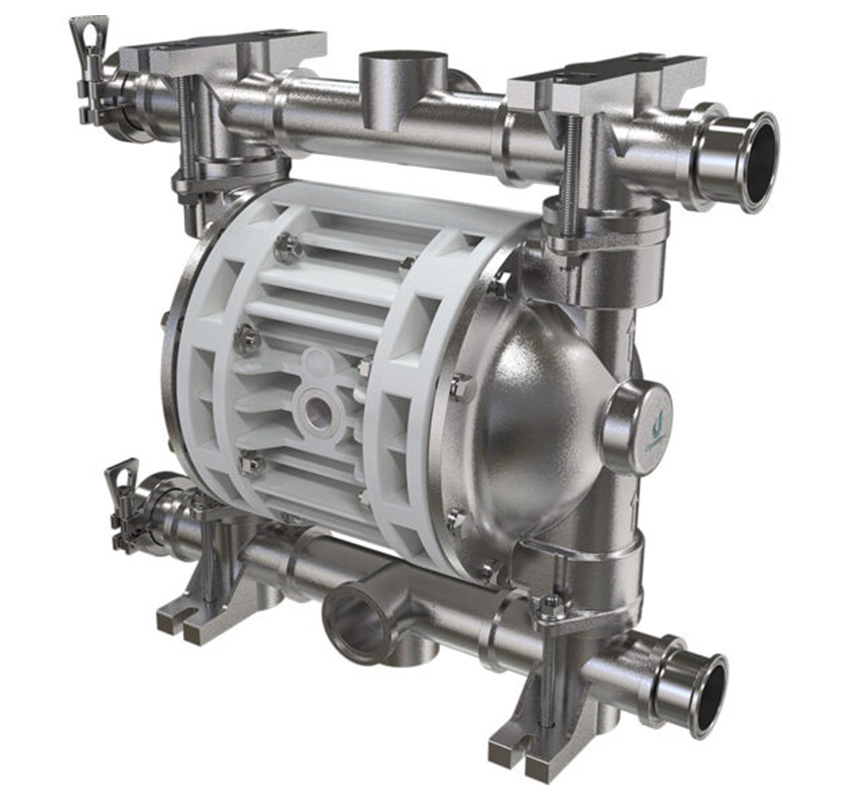

In areas with sensitive hygienic requirements, cleanliness is a critical factor. SEEPEX food and hygienic pumps fulfill even the strictest hygiene requirements in the food, pharmaceutical, cosmetics and chemical industries, conveying both high- and low-viscosity substances with minimal shear effect. They ensure product quality at all times in compliance with 3-A Sanitary Standards.

The components of our food and hygienic pumps are designed in compliance with EHEDG principles. The BCFH range even has certification to mark it as particularly hygienic and easy to clean. All materials in contact with the pumping product naturally fulfill the international requirements of the FDA and EU 1935-2004.

Features and Benefits

Fulfills the strictest hygiene and material standardsr

EHEDG-certified (BCFH range) and compliant with the strictest FDA and 3-A hygiene and material standards through optimized intake geometries, certified components and hygienic mechanical seals

Gentle conveyance

Low shear and virtually pulse-free pumping of low to highly viscous products with constant conveying capacities and high pressure stability

Residue-free cleaning

Optimal results thanks to cleaning processes such as Clean in Place (CIP), Sterilization in Place (SIP), Clean out of Place (COP)

Easy maintenance

Low space requirements and no special tools required for maintenance – simply release the Flexrod from the rotor and drive shaft (BCFH and BCF ranges)

Versatile applications

Fulfills even the strictest hygiene requirements, and is therefore suitable for numerous applications in the food, pharmaceutical, cosmetics and chemical industries

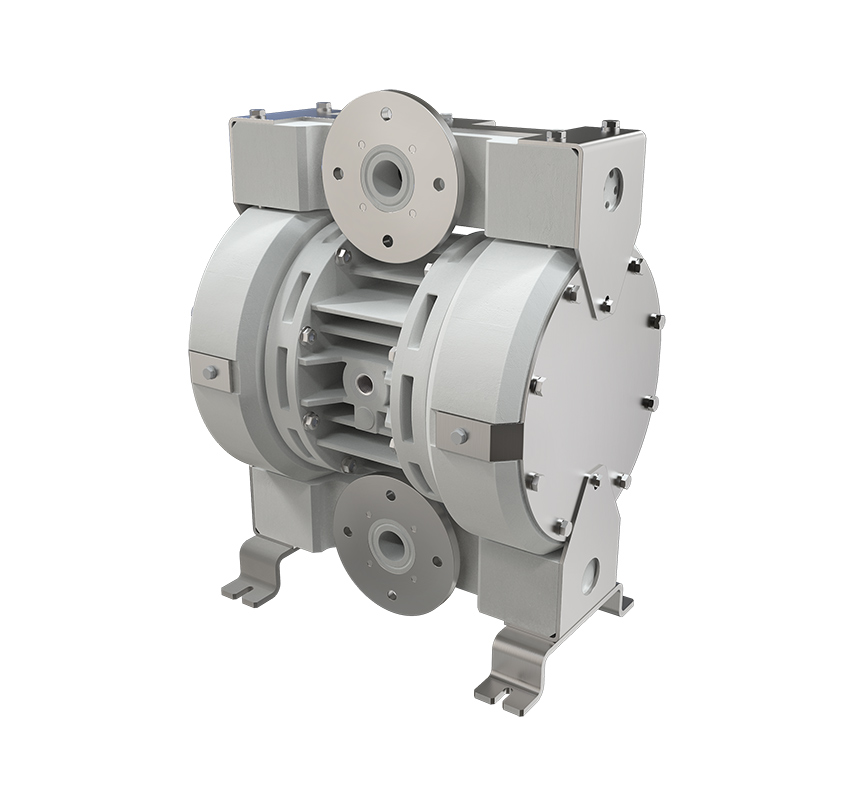

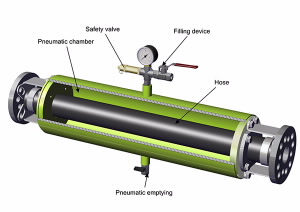

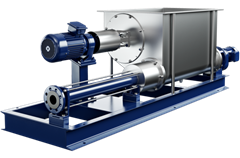

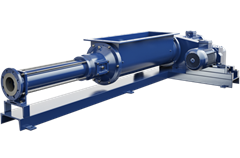

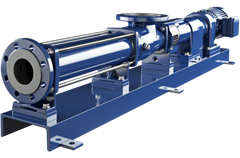

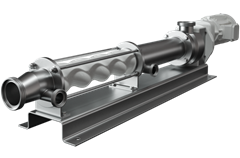

BCF - FLEXROD DESIGN

Rotating unit with joint-free flexible titanium shaft

Conveying Capacity

0.09–60 m³/h

0.4–264 US gpm

Pressure

≤ 24 bar

≤ 350 psi

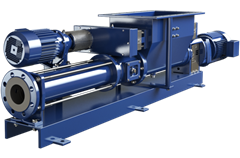

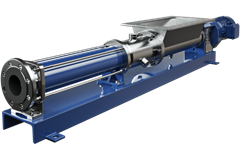

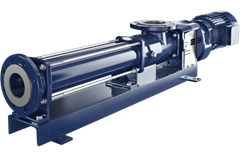

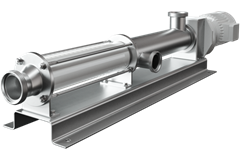

BCFH - EHEDG CERTIFIED

Cleaning and sterilization with EHEDG type EL Class I certificate awarded

Conveying Capacity

0.09–60 m³/h

0.4–264 US gpm

Pressure

≤ 24 bar

≤ 350 psi

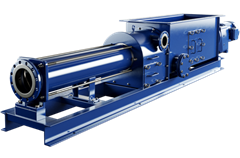

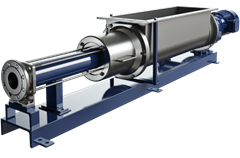

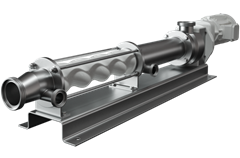

BCSO - Open pin joints

Open hygiene joints, residue-free cleaning using CIP

Conveying Capacity

0.03–130 m³/h

0.132–572 US gpm

Pressure

≤ 24 bar

≤ 350 psi

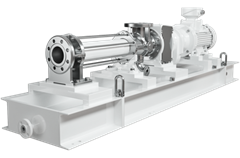

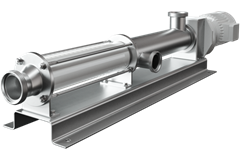

BCSB - CLOSED PIN JOINTS

Closed pin joint, suitable for conveying abrasive media

Conveying Capacity

0.03–130 m³/h

0.132–572 US gpm

Pressure

≤ 24 bar

≤ 350 psi

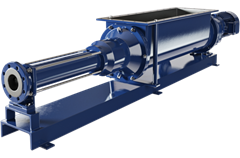

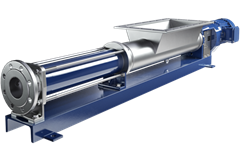

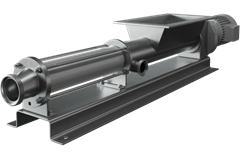

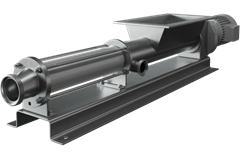

BTCS - HOPPER PUMP IN HYGIENIC DESIGN

With choice of open or closed pin joint

Conveying Capacity

0.03–130 m³/h

0.132–572 US gpm

Pressure

≤ 24 bar

≤ 350 psi